PRODUCT

صفحة رئيسية>منتجات>

primary crushing iron ore

Iron Ore Processing: From Extraction to Manufacturing

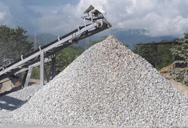

2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments. The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation 2022年1月1日 The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of Comminution and classification technologies of iron oreSix steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. The six main steps of iron ore processing - Multotec

Primary Crusher Optimisation for Improved Comminution

primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher. As the term ‘primary’ implies, these crushers are The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter Primary Crusher - an overview ScienceDirect Topics2022年8月18日 The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system A Mine-to-Crusher Model to Minimize Costs at a

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation This paper briefly reviews the background of mobile primary crushers and their current main areas of application. The benefits of applying mobile primary crushing and belt Application of Mobile Primary Crushing and Belt Conveying Primary crushing brings run-of-mine ore down to a maximum size of the order 4" to 6" in average diameter; secondary crushing receives feed at -6" and reduces it to below tn. PRIMARY CRUSHING

Primary Crushing SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below

- صوره ماكينة الزجاج

- أدلى مطاحن الكرة في ألمانيا لعدم مسحوق

- تقرير جدوى حول صناعة صنع كتلة في نيجيريا

- iron ore crusher design applications

- low grade limonite iron ore beneficiation study

- نيوزيلندا آلة تكسير الحجر 310 tph

- simple iron ore process

- الحديد المعدات إثراء خام خام الحديد

- شكل ماكنة براون الجديده للتقشير

- magnetite iron ore processing flow sheet

- distributor cruser iron ore indonesia

- positive impact on quarrying iron ore

- بريدجبورت طحن ميشيغان

- آیکون چرخ الکتریکی می باشد

- قائمة أسعار المطحنة الرطبة لشركة الجانج

- hosmic سحق في الماسية

- كثافة الحصى المسحوق 6 حجم

- what kind of stones have iron ore

- iron ore beneficiation plant china technology

- تطبيق برنامج في التعدين بييونيبو الغربية الألغام