PRODUCT

صفحة رئيسية>منتجات>

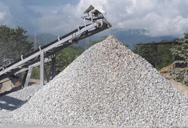

iron ore production type crusher

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments. The primary objective of 2022年1月1日 Hematite and magnetite iron ores are the most prominent raw materials for iron and steel production. Most of the high-grade hematite iron ores are typically Comminution and classification technologies of iron ore2024年2月25日 Iron ore processing is a critical step in the steel production process, and selecting the right crusher is essential to ensure the efficiency and productivity of the The factors to choose a crusher during iron ore processing

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be provided with almost any type Primary Crusher Optimisation for Improved Comminution2024年5月28日 Iron ore crushing plants are divided into two types: fixed iron ore crushing plant and mobile iron ore crushing plant. For projects with complex 5 Types of Iron Ore Crushing Plants for Sale

Iron Ore Production Line - CM Mining Machinery

In the iron ore crushing production process, there are generally two types of secondary crushers: either fine jaw crushers or cone crushers. The fine jaw crusher is generally 2022年8月18日 The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system A Mine-to-Crusher Model to Minimize Costs at a Production line is introduced: the iron ore crusher has been widely used in mining, metallurgy, chemical, building materials, roads, railways, water and other industries. the applied material consist of hematite, magnetite, Iron Ore Crusher Plant, Iron Ore Crushing And

Iron ore crushing and screening process - Ultrafine Powder

2022年8月3日 In the iron ore crushing production process, there are generally two types of secondary crushers: fine jaw crusher or cone crusher. The fine jaw crusher is

- توپ سنگ زنی تامین آسیاب

- الشركات المحجر الاتصال في كل بلد

- 900x900 الأسطوانة الكرة مطحنة

- دف 310 الطاحن السعر في باكستان

- مطحنة الكرة للأسمنت نوع الدفعة

- best use of ferro silicon in mining iron ore

- كسارة مخروطية تحمل خرطوم فائض

- التجميع والتف خط إنتاج سحق الفك من هونج كونج

- تأثير الصدم تأثير المتانة

- مطرقة مطحنة عمان المصنعة في مصر

- h c moulins davis a vendre

- إيجابيات ميسين المطرقة مطحنة

- مطرقة طن شبكة الشاشة

- الرمال الناعمة تهتز الشاشة المورد

- التعدين والحصى الرمل إلينوي

- سبب ل مطحنة الفحم الاهتزاز ساماك محطم

- تعقب كسارة الفك المحمول في مصر

- عبد الغفور الشيخ طاحونة

- آلة طحن الصين المورد

- عملية الذهب في رومانيا