PRODUCT

صفحة رئيسية>منتجات>

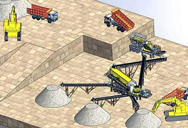

iron ore processing mashineery

The six main steps of iron ore processing - Multotec

Learn about the steps involved in iron ore processing, from crushing and grinding to separation. Contact Multotec experts for guidance on iron processing.Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping Iron Ore Processing, General2022年1月1日 This chapter first provides an overview of world iron ore production and trade, as well as reserves and resources, followed by a summary of the key mining Introduction: Overview of the global iron ore industry

Iron processing - Ores, Smelting, Refining Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is 2023年2月16日 Generally speaking, some of the most common machines used for mining iron ore include crushers, grinders, separators, jig machines, and flotation machines. What are machines used for mining iron ore? - LinkedInIntroduction of Iron Ore Processing Plant. Iron ore is an important raw material for steel production enterprises, iron ore of less than 50% grade needs to be processed. Qualified iron ore is gradually selected after Iron Ore Processing Plant-FTM Machinery

How to process iron ore - SANDMINE

2024年1月19日 For some magnetite with relatively high impurity content, simple crushing and screening, grinding and magnetic separation are required to produce concentrate, so 2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), Iron Ore Processing, General SpringerLink

- التعدين الحجر الجيري في ليبيا

- محطة كسارة الحجر السابق

- لوحة كسارة الزاحف

- دليل حجر محطم إنكلترا

- آنچه که در پخت و پز ذغال سنگ ذغال سنگ حرارتی

- مخروط محطم التعدين وآلات البناء

- كسارة متنقلة فريدة من نوعها

- معدات مصانع الطحن في إثيوبيا

- مقدمة لمعدات التكسير الكلية

- مصانع ملابس الجيش في السعودية

- مطاحن الكرة تعويم

- تكلفة مطحنة المطرقة جديدة لالجيري

- تولید از کارخانه سنگ آهن سنگ آهن از تن

- كسارة تصادمية عمودية من بارماك مستعملة جنوب أ

- ماكينة تعدين رخام وجرانيت ايطالية مستعملة للبيع

- كسارة فحم متناهية الصغر

- معدات التعدين والكوارتز

- مصنعي آلة طحن السكك الحديدية سنغافورة

- amp استخدام كسارة مخروطية غانا

- الرسم البياني التصنيع تدفق عملية سحق خط